Введение в продукт

Эта установка по производству NPK-удобрений предлагает комплексное решение для создания сбалансированных удобрений, сочетая долгосрочные преимущества органических веществ для питания почвы с быстродействующими, необходимыми неорганическими питательными веществами (азот, фосфор, калий). Наши полностью настраиваемые системы позволяют производить высокоэффективные удобрения, адаптированные к конкретным требованиям культур и почвенным условиям, поддерживая устойчивое сельское хозяйство и снижая чрезмерную зависимость от исключительно синтетических веществ.

Параметр

|

Модель

|

Внутренний диаметр

т/чмZG1240

|

Наклон

(° ZG1240

|

Скорость вращения (

т/ч ) ZG1240

|

(

т/ч )ZG1240

|

(

т/ч ) ZG1240

|

|

1.2

|

2-5

|

3

|

5.5

|

1-3

|

ZG1450

|

|

1.4

|

2-5

|

3

|

11

|

3-4

|

ZG1560

|

|

1.5

|

2-5

|

3

|

11

|

5-8

|

ZG1870

|

|

1.8

|

2-5

|

3

|

18.5

|

8-10

|

ZG2080

|

|

2

|

2-5

|

3

|

18.5

|

10-15

|

ZG2290

|

|

2.2

|

2-5

|

3

|

22

|

15-20

|

ZG24100

|

|

2.4

|

2-5

|

3

|

30

|

20-25

|

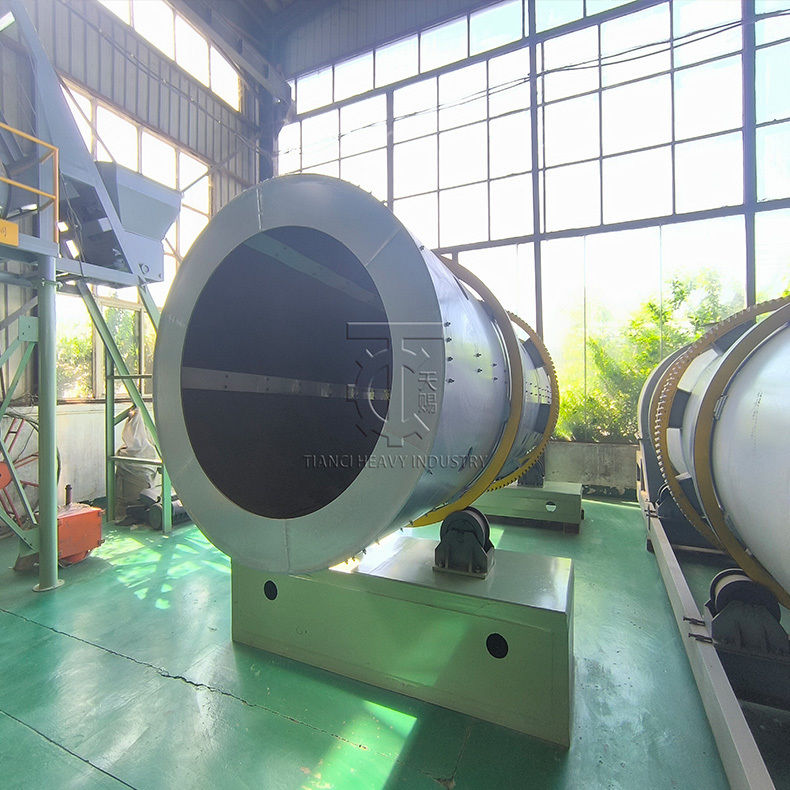

Рабочий процесс

|

1. Подготовка сырья:

NPK, органические материалы (например, навоз, остатки сельскохозяйственных культур) подвергаются ферментации (для разложения и стерилизации) и дроблению; неорганические материалы измельчаются и предварительно обрабатываются для обеспечения однородного размера частиц для смешивания.2. Автоматическое дозирование и смешивание:

Система автоматически дозирует и смешивает подготовленные органические и неорганические материалы в соответствии с целевой формулой удобрения, обеспечивая однородное смешивание.3. Гранулирование:

Смешанный материал подается в гранулятор (роторный барабан, диск или экструдер) для формирования сферических или цилиндрических гранул желаемого размера.4. Сушка:

Гранулы сушат при низкой температуре (приблизительно 90°C), сохраняя термочувствительные органические компоненты и полезные микробы, снижая влажность до 10-15%.5. Охлаждение:

Высушенные гранулы охлаждаются до комнатной температуры с помощью системы охлаждения, стабилизируя их структуру и предотвращая повторное поглощение влаги.6. Сортировка:

Гранулы проходят через вибросито для отделения частиц большего/меньшего размера (которые возвращаются на стадию смешивания) и сохранения продуктов однородного размера.7. Дополнительное покрытие:

Однородные гранулы покрываются (при необходимости) функциональными материалами для улучшения контроля высвобождения питательных веществ или антислеживающихся свойств.8. Упаковка:

Готовые гранулы автоматически взвешиваются, засыпаются в мешки (25 кг, 50 кг или навалом) и запечатываются для хранения или отгрузки.Вопросы и ответы

В:

Не могли бы вы указать диапазон почасовой производительности вашего барабанного гранулятора? О:

В:

Сколько NPK-удобрений может произвести барабанный гранулятор за один год? О:

Стандартная почасовая производительность нашего барабанного гранулятора составляет от 1 до 25 тонн. Если у вас есть более высокие требования к производительности (например, более 25 тонн в час), мы можем разработать индивидуальное решение, основанное на ваших конкретных производственных потребностях.В:

Не могли бы вы указать диапазон почасовой производительности вашего барабанного гранулятора?Не могли бы вы подтвердить, доступны ли услуги по установке барабанного гранулятора после его покупки?О:

Стандартная почасовая производительность нашего барабанного гранулятора составляет от 1 до 25 тонн. Если у вас есть более высокие требования к производительности (например, более 25 тонн в час), мы можем разработать индивидуальное решение, основанное на ваших конкретных производственных потребностях.В:

Не могли бы вы указать диапазон почасовой производительности вашего барабанного гранулятора? О:

Стандартная почасовая производительность нашего барабанного гранулятора составляет от 1 до 25 тонн. Если у вас есть более высокие требования к производительности (например, более 25 тонн в час), мы можем разработать индивидуальное решение, основанное на ваших конкретных производственных потребностях.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!